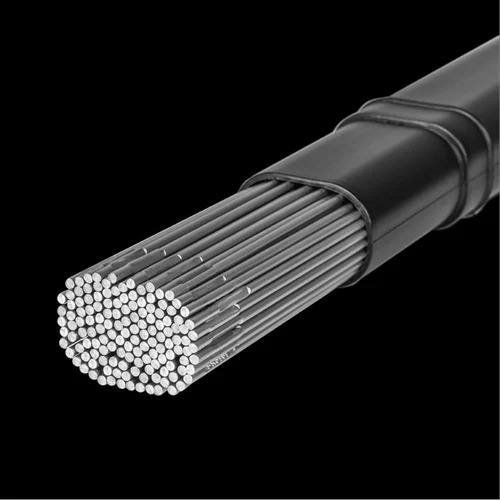

304L ER Stainless Steel Tig Wire

190 INR/Kilograms

Product Details:

- Conductor Type Solid

- Temperature Up to 870C (service temperature)

- No Of Core Single

- Product Type TIG Welding Wire

- Material 304L ER Stainless Steel

- Function Filler material for TIG welding of stainless steels

- Usage Industrial, Fabrication, Pipe Welding, Sheet Metal

- Click to view more

X

304L ER Stainless Steel Tig Wire Price And Quantity

- 15 Kilograms

- 190 INR/Kilograms

- >30%

- C: 0.03%, Cr: 18-20%, Ni: 8-12%, Mn: 2.0%, Si: 1.0%, S: 0.03%, P: 0.045%

- Excellentsuitable for chemical, food, and pharmaceutical industries

- 100% Argon recommended

- ER304L

- Plastic Tubes, Spools, or Coils

- AWS A5.9, ASME SFA 5.9

- >=320 MPa

- Bright, Clean

- >=550 MPa

304L ER Stainless Steel Tig Wire Product Specifications

- Industrial, Fabrication, Pipe Welding, Sheet Metal

- None (Bare Wire)

- Solid

- Filler material for TIG welding of stainless steels

- Stainless Steel

- TIG Welding (GTAW) of 304/304L Stainless Steels

- 1.2 mm, 1.6 mm, 2.0 mm, 2.4 mm, 3.2 mm

- Up to 870C (service temperature)

- Silver/Grey (Metallic)

- 1 meter (typical; coils/spools available)

- 1.6 mm, 2.0 mm, 2.4 mm, 3.2 mm (custom sizes available)

- 304L ER Stainless Steel

- TIG Welding Wire

- Single

- >30%

- C: 0.03%, Cr: 18-20%, Ni: 8-12%, Mn: 2.0%, Si: 1.0%, S: 0.03%, P: 0.045%

- Excellentsuitable for chemical, food, and pharmaceutical industries

- 100% Argon recommended

- ER304L

- Plastic Tubes, Spools, or Coils

- AWS A5.9, ASME SFA 5.9

- >=320 MPa

- Bright, Clean

- >=550 MPa

304L ER Stainless Steel Tig Wire Trade Information

- Domestic

- 100 Kilograms Per Day

- 7 Days

- Yes

- Within a certain price range free samples are available

- Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, , South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Chandigarh, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Tripura, West Bengal, Bihar, All India, Uttar Pradesh, Maharashtra, Delhi, Gujarat, Telangana, Central India, Odisha, West India, Chhattisgarh

Product Description

Stainless Steel ER 304L Tig Wire

Technical Specifications

Diameter | 0.04 to 16mm |

Finishing | Polished |

Grade | SS304L |

Packing Type | Spool |

Technique | Hot Rolled |

Material | Stainless Steel |

Exceptional Corrosion Resistance

The 304L ER stainless steel TIG wire is specifically designed for superior resistance to corrosion, making it optimal for environments exposed to chemicals, moisture, and food products. Its low carbon content minimizes carbide precipitation, guaranteeing reliable performance in industries such as pharmaceuticals and food processing.

High Mechanical Strength

With a tensile strength of at least 550 MPa and yield strength of at least 320 MPa, this TIG wire provides robust welds with excellent elongation (>30%), ensuring structural integrity in both fabrication and pipe welding jobs, even under demanding industrial conditions.

Versatile Applications

Suitable for TIG welding (GTAW) of 304 and 304L stainless steel, this filler wire is widely utilized in sheet metal work, pipe welding, and industrial fabrication. Its solid conductor and bright finish make it a preferred choice for precision jobs requiring clean and durable welds.

FAQs of 304L ER Stainless Steel Tig Wire:

Q: How is 304L ER Stainless Steel TIG Wire used in welding?

A: 304L ER Stainless Steel TIG Wire serves as a filler material during TIG welding (GTAW) of 304/304L stainless steels. It is fed manually or mechanically into the weld pool, creating strong, corrosion-resistant joints ideal for industrial and fabrication purposes.Q: What industries commonly benefit from using ER304L TIG wire?

A: Industries such as chemical processing, food manufacturing, and pharmaceuticals benefit most from ER304L TIG wire due to its excellent corrosion resistance, bright surface finish, and reliable mechanical properties.Q: When should I choose ER304L TIG wire over other grades?

A: ER304L TIG wire should be used when welding applications require low carbon content to prevent intergranular corrosion, especially in environments involving chemicals, high humidity, or food products. It is preferred for welding 304 or 304L stainless steels.Q: Where is 304L ER TIG Wire typically supplied and distributed in India?

A: 304L ER TIG Wire is available through an extensive network of distributors, suppliers, exporters, importers, and traders across India, making it accessible for various industrial and fabrication needs.Q: What shielding gas is recommended when welding with ER304L TIG wire?

A: 100% Argon is the recommended shielding gas for TIG welding with ER304L wire. Argon ensures a stable arc, minimizes oxidation, and promotes clean, high-quality welds on stainless steel surfaces.Q: How does the chemical composition of ER304L TIG wire enhance its performance?

A: The low carbon content (0.03%) paired with optimal chromium and nickel percentages in ER304L TIG wire boosts corrosion resistance and mechanical strength. These features make it suitable for demanding, high-temperature environments up to 870C.Q: What packaging options are available for 304L ER Stainless Steel TIG Wire?

A: The wire is typically supplied in plastic tubes, spools, or coils, ensuring safe transport and convenient handling at the worksite, with lengths of 1 meter as standard and customized sizing as required.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese